Driving A Legacy

Fleetwood is one of the oldest names in the RV industry. We’ve been around for over 65 years—more than double most of our competition. And that resilience speaks to our product. After all, a company can’t stay in business if they build something people don’t believe in. But Fleetwoods are the most popular RVs on the road*—and it’s easy to see why.

Below are some of the features that set Fleetwood apart from everyone else.**

The Science of RV Design

Inherently motorhomes are just that—a little bit vehicle, a little bit house. So at Fleetwood, we engineer and build them with both in mind. Our innovation shows we perfectly balance and blend the two. And that smarter design means a better RV.

Powerlock System™

Our exclusive interlocking aluminum extrusion wall-joint system integrates floor, sidewall and roof assembly into one overall structure for long-term performance and durability.

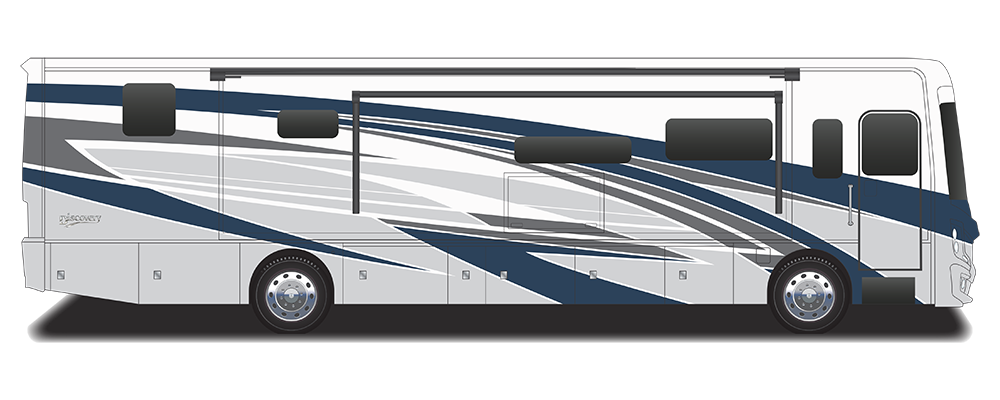

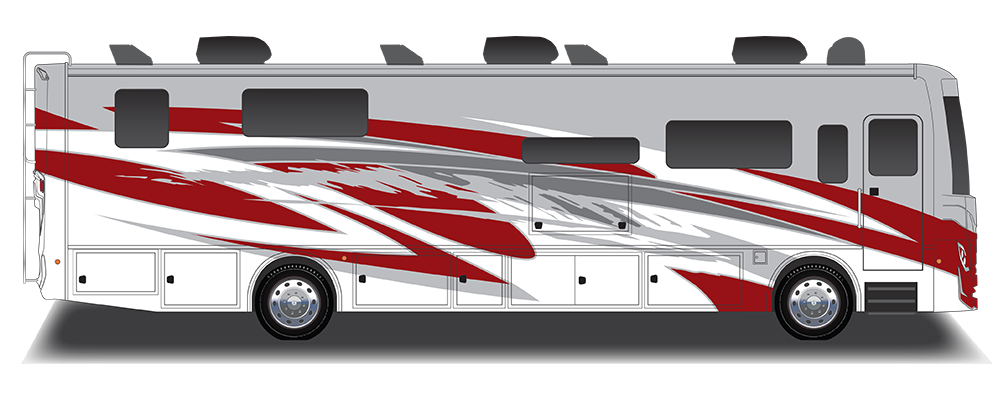

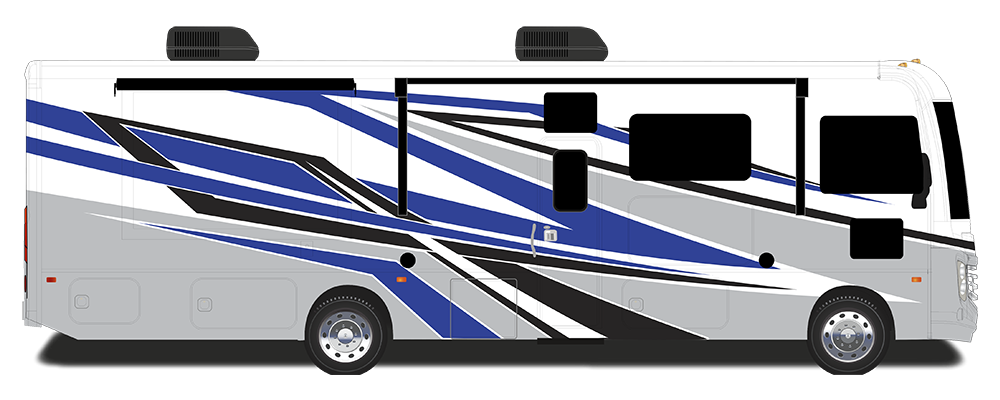

Premium Full-Body Paint

We apply up to four different colors and as many as two separate coats of clear in our state-of-the-art facility. Not only does it make our RVs look great, but it protects them and means better resale values.

Roto-Cast Molded & Citadel Lined Luggage Bays

Instead of the typical plywood, our molded bays are more durable, look great and can be washed with a hose.

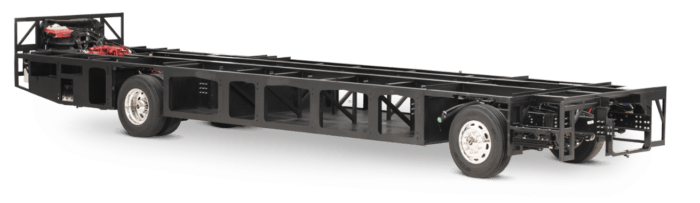

Our Exclusive Chassis

Fleetwood Freedom Bridge® (Diesel Only)

Our proprietary all-steel structure creates a true side-to-side, front-to-rear and belly-to-beltline bridging platform that pairs perfectly with the Freightliner XCM® chassis. We specifically design them for each Class A Diesel floorplan, improving reliability and handling, and increasing basement storage. Click here to learn more about the Freedom Bridge®.

![FreedomBridge[1] FreedomBridge[1]](https://www.fleetwoodrv.com/wp-content/uploads/2021/05/FreedomBridge1.png)

Fleetwood Power Platform® (Gas Only)

For our exclusive gas chassis, we take the Ford® drivetrain and create a solid platform to build on. The result is enhanced balance and control, as well as the strength to carry more weight. Additionally, the design allows for larger pass-through storage.

![power-platform-img@2x[1] power-platform-img@2x[1]](https://www.fleetwoodrv.com/wp-content/uploads/2021/05/power-platform-img@2x1.png)

State-of-the-Art Materials &

Construction

![auto-level[1] auto-level[1]](https://www.fleetwoodrv.com/wp-content/uploads/2021/05/auto-level1.jpg)

Automatic Hydraulic Leveling System

Our four-point hydraulic system is more reliable than electric jacks and provides smooth and simple leveling at the push of a button.

Vacu-Bond™ Construction

We apply 415,000 pounds of vacuum pressure for 30 minutes to create some of the straightest, flattest and strongest walls on the market.

Solid Bead-Foam Engineered Fit Insulation™

Using exact measurements, we place bead-foam between every structural support to eliminate air holes and provide superior temperature and sound insulation.

Dryseal™ Edge Coating

We coat every edge of the walls and windows to wick away water, seal out moisture, and prevent delamination, swelling and mold.

Tuff Coat Fiberglass Walls

Our UV and weather-resistant fiberglass skin is not adhered to wood substrate, meaning there is much less chance of delamination.

TPO Engineered Vinyl Roofing

Resilient and low-maintenance thermoplastic polyolefin or “Tuff-Ply” is flexible and easily conforms to the roofline radius with little to no stress at the awning rail connection seam.

Tapered Slideout Box Tops

By slightly pitching our slideout box rooflines, water is directed away from our RVs, providing an additional level of moisture protection.

Seamless Metallic Slide Room Underbellies

We cover our slideout bottoms with metal as an extra safeguard against the elements.

Full-Length Metallic A/C Ducting

We ditch the cut-out foam channels in favor of insulated ducting that runs the entire length of the RV, placing outlets in the most occupied places to assure cool comfort.

Sure-Glide Flush Floor Aluminum Slide Transition Ramps

Our aluminum ramps are much more durable and reliable than the industry-standard pinewood, which absorb moisture, crack and rot.